Our MPP (Modified Polypropylene) Cable Protection Pipe is a high-performance conduit engineered for modern trenchless installation methods. Manufactured from premium-grade modified polypropylene, this pipe is specifically designed to protect power and communication cables in demanding environments without the need for extensive excavation

. Its unique combination of high strength, temperature resistance, and durability makes it the ideal solution for installing cables under roads, railways, buildings, and riverbeds, minimizing environmental impact and project timelines . With a service life exceeding 50 years and compliance with international standards, it offers a reliable, cost-effective alternative to traditional piping materials .

Key Advantages

-

Exceptional Strength & Durability

The pipe exhibits superior tensile and compressive strength, outperforming standard HDPE pipes

. With ring stiffness grades ranging from SN24 to SN40, it can withstand substantial ground pressure and heavy loads, making it suitable for burial depths from 2 to over 4 meters without deformation . -

High-Temperature & Chemical Resistance

Engineered for a broad working temperature range of -5°C to 120°C (capable of withstanding short-term spikes up to 150°C), our MPP pipe ensures performance in challenging thermal conditions, such as cable overloads

. It also offers outstanding resistance to corrosive substances, including acids, alkalis, and salts, ensuring longevity in aggressive soil conditions . -

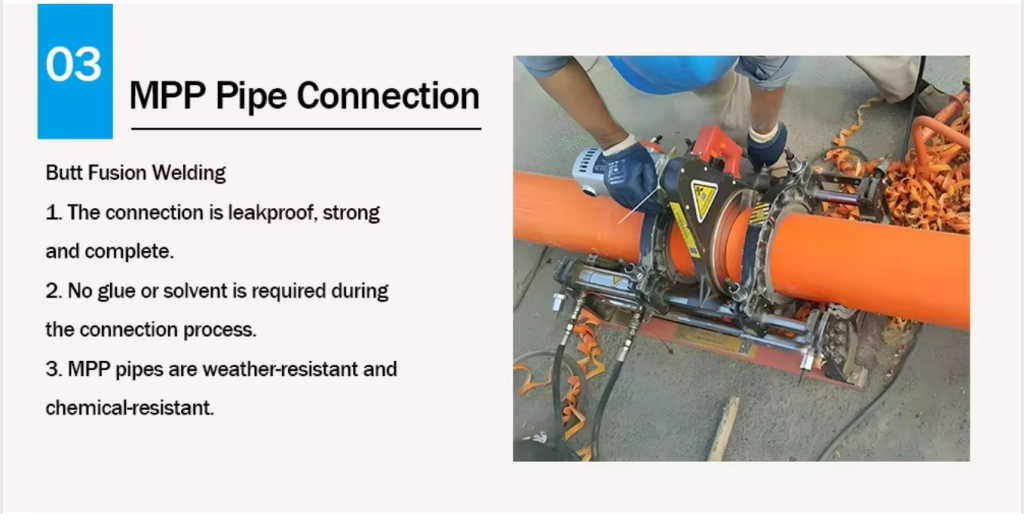

Efficient Trenchless Installation

The lightweight design (approximately 1/8 the weight of steel pipes) and smooth inner wall significantly reduce friction, simplifying cable pulling

. Its primary connection via hot-melt butt welding creates a monolithic, leak-proof joint that is stronger than the pipe itself, ensuring a seamless and secure pipeline system . This method eliminates the need for extensive digging, reducing disruption, traffic delays, and overall project costs by up to 30% . -

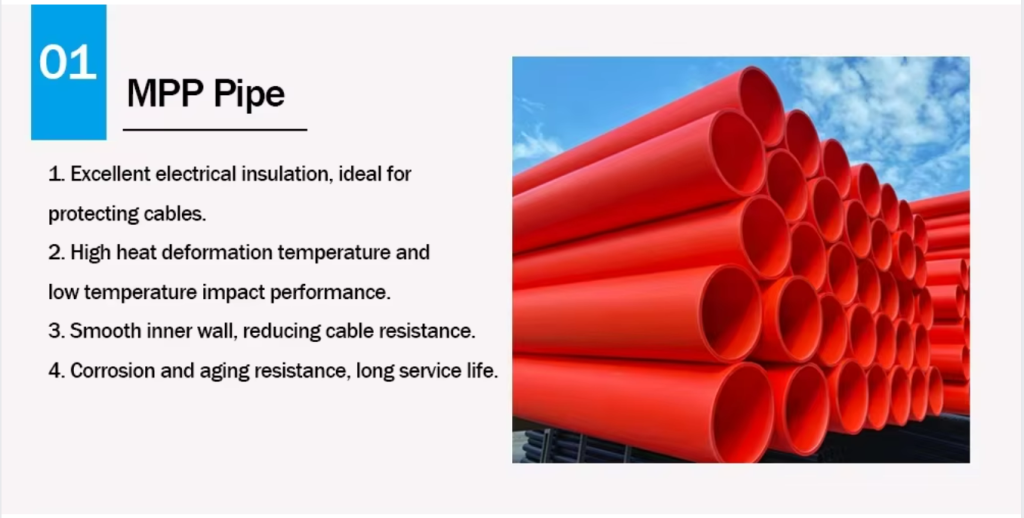

Superior Safety & Insulation

The material provides excellent electrical insulation properties, preventing current leakage and ensuring optimal safety for high-voltage power cable applications (ideal for 10KV and above)

. Its non-conductive nature and flame-retardant properties enhance safety in public spaces and sensitive installations .