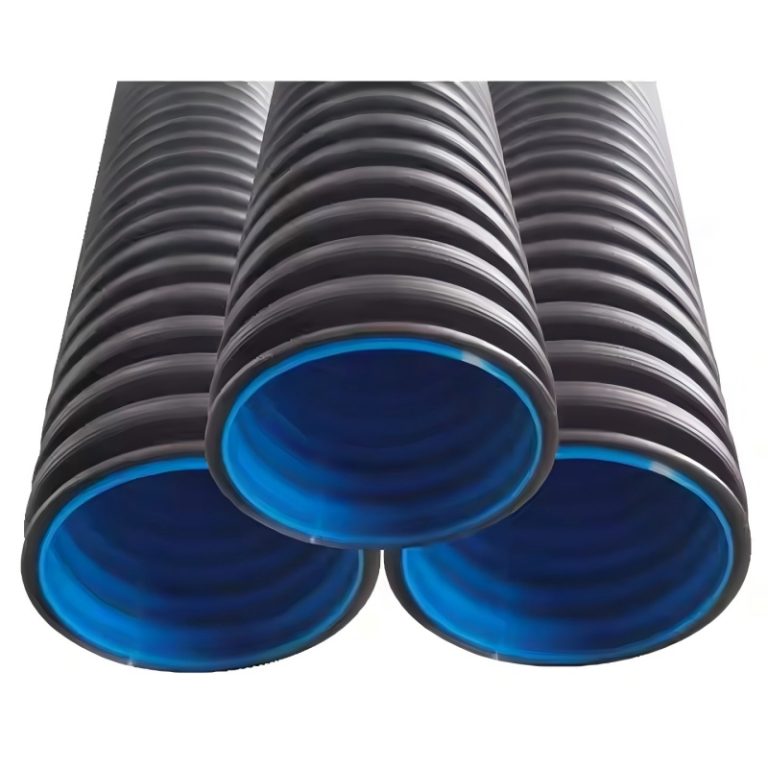

Double-wall corrugated pipe is an innovative thermoplastic piping solution engineered with a unique structural design: a smooth inner wall for optimal flow efficiency and a corrugated outer wall for enhanced mechanical strength. Manufactured from high-density polyethylene (HDPE), this pipe combines exceptional durability with practical installation advantages. It is designed to replace traditional materials like concrete, metal, or solid-wall plastic pipes in demanding applications such as municipal drainage, industrial sewage systems, agricultural irrigation, and cable protection. With a service life exceeding 50 years and compliance with international standards (ISO, GB, CE), it offers a reliable and cost-effective solution for modern infrastructure projects

Key Advantages

Lightweight & Easy Installation

Weighing as little as 1/8 of steel or concrete pipes, the pipe reduces transportation and labor costs. Its flexibility allows bending without additional fittings, enabling trenchless installation and adaptation to uneven terrain. Connections via butt fusion, electrofusion, or mechanical joints ensure leak-proof, monolithic systems.

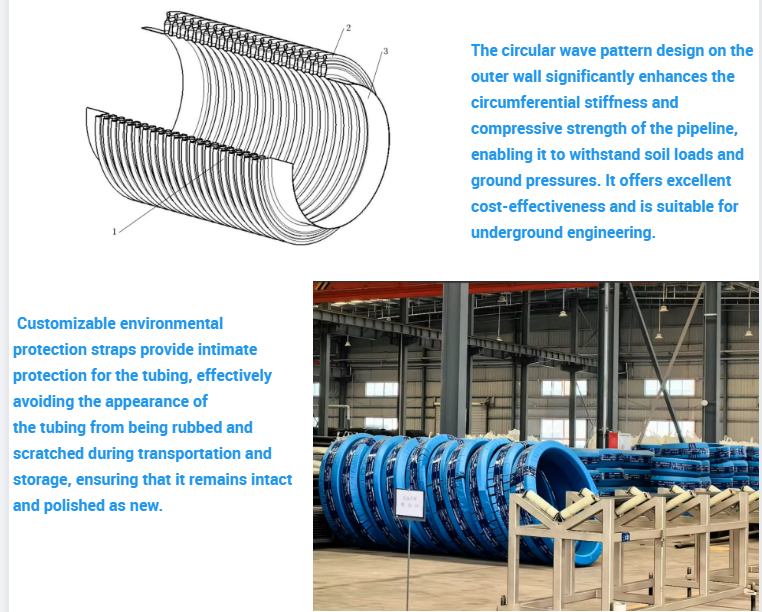

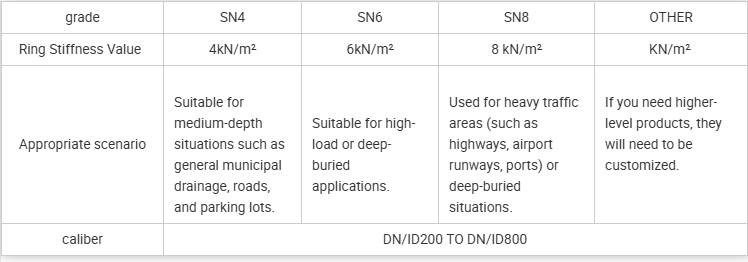

High Ring Stiffness

The annular corrugated outer wall provides superior resistance to external loads, with ring stiffness ratings ranging from SN4 to SN16 (e.g., SN8/Sn10/Sn12.5). This design allows the pipe to withstand soil pressure, vehicle loads, and harsh environmental stresses without deformation, making it ideal for deep-burial applications.

Superior Chemical & Corrosion Resistance

HDPE’s non-polar molecular structure resists acids, alkalis, salts, and abrasive fluids. Unlike metal pipes, it eliminates rust, scaling, and electrochemical degradation, ensuring long-term performance in corrosive soils or industrial effluents

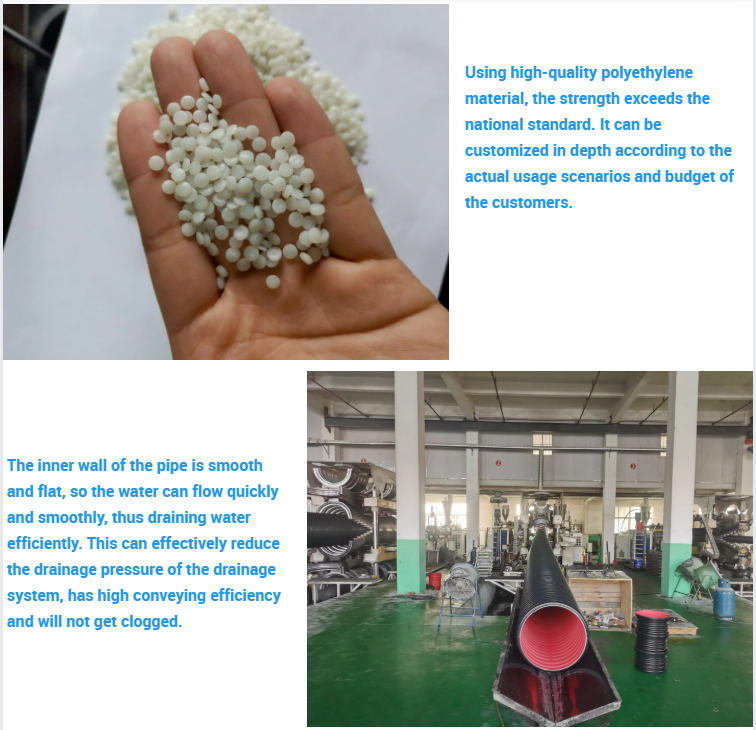

Hydraulic Efficiency & Durability

The smooth inner surface (Manning coefficient: 0.009) minimizes friction loss, increasing flow capacity by up to 30% compared to conventional pipes. Its impact resistance and flexibility prevent cracking under pressure or ground movement, with operational tolerance from -60°C to 60°C

Economic & Environmental Benefits

The double-wall structure uses 30–50% less material than solid-wall alternatives, lowering costs without compromising strength. As a 100% recyclable, non-toxic material, it prevents environmental contamination and reduces carbon footprint during production and installation