Our HDPE Butt Fusion Welding Machine is engineered to create strong, permanent, and leak-proof joints for thermoplastic pipes made of PE (Polyethylene), PP (Polypropylene), and PVDF (Polyvinylidene Fluoride). Utilizing a proven thermofusion process that heats pipe ends and fuses them under controlled hydraulic pressure, this machine ensures joint integrity that meets or exceeds the strength of the pipe itself

. It is an indispensable solution for a wide range of applications, including potable water supply, gas distribution, industrial pipelines, and sewage systems . Designed for both field and workshop use, it combines robust performance with user-friendly operation to achieve consistent, high-quality welds critical for modern infrastructure projects .

Key Features & Advantages

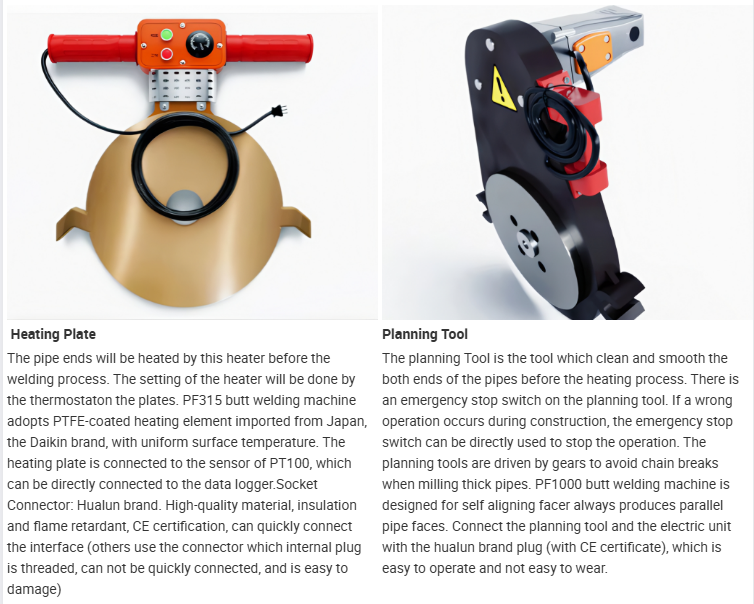

Precision Temperature Control: Equipped with a removable, PTFE-coated heating plate that ensures a uniform surface temperature with minimal deviation (typically < ±5°C), which is crucial for a consistent and flawless fusion joint

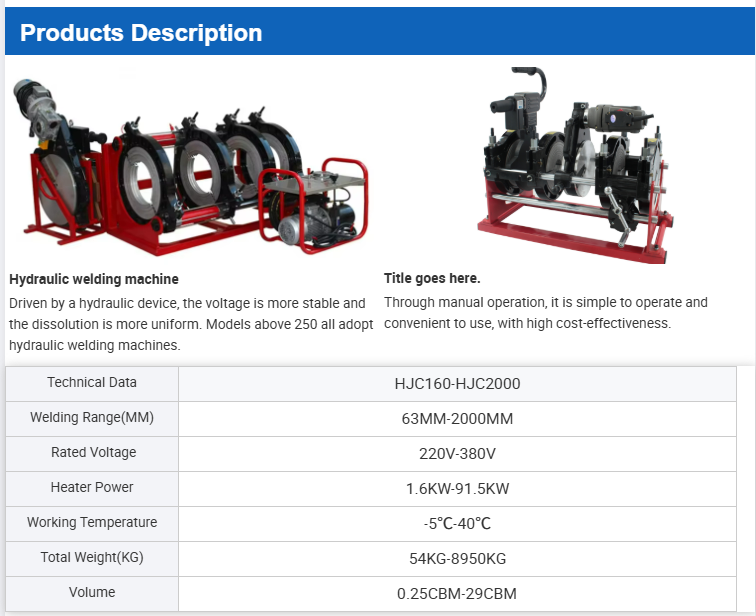

. The digital controller allows for accurate temperature settings up to 270°C .Robust Hydraulic System: The machine incorporates a reliable hydraulic unit that delivers stable and consistent pressure throughout the fusion process. This system features a high-accuracy, shockproof pressure gauge and adjustable pressure ranges (e.g., 0-6.3 MPa) to suit various pipe sizes and standards

.Versatile Material Compatibility: Specifically designed to work with a broad spectrum of thermoplastic materials, including HDPE (PE80/PE100), PP, and PVDF, making it a single solution for diverse project requirements

.Durable and User-Friendly Design: Constructed from high-strength, lightweight aluminum alloy, the machine is built for durability and portability

. Features like an electric planing tool with a safety switch, a dual-channel timer for heating and cooling phases, and clear, well-organized controls simplify operation and enhance safety on the job site .Wide Pipe Size Range: Available in multiple models to accommodate a vast range of pipe diameters, from small-scale lines starting at 20mm to large-diameter pipes exceeding 1200mm, ensuring the right tool for every job