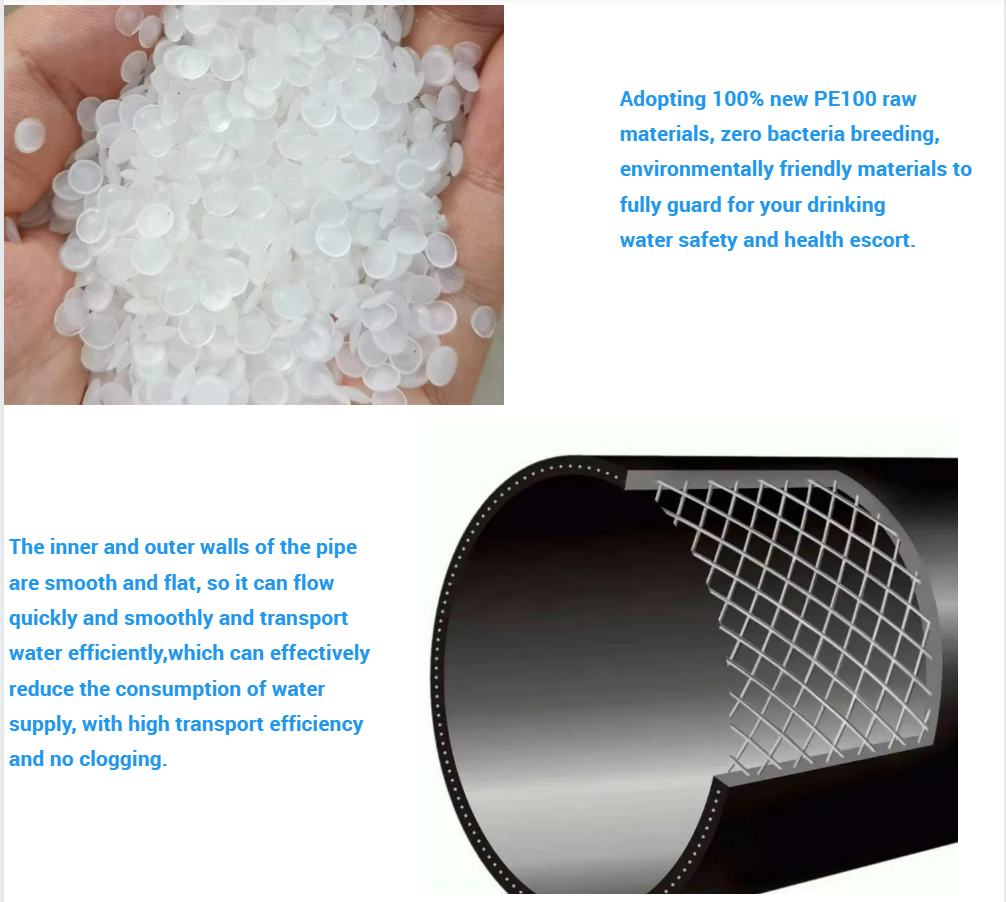

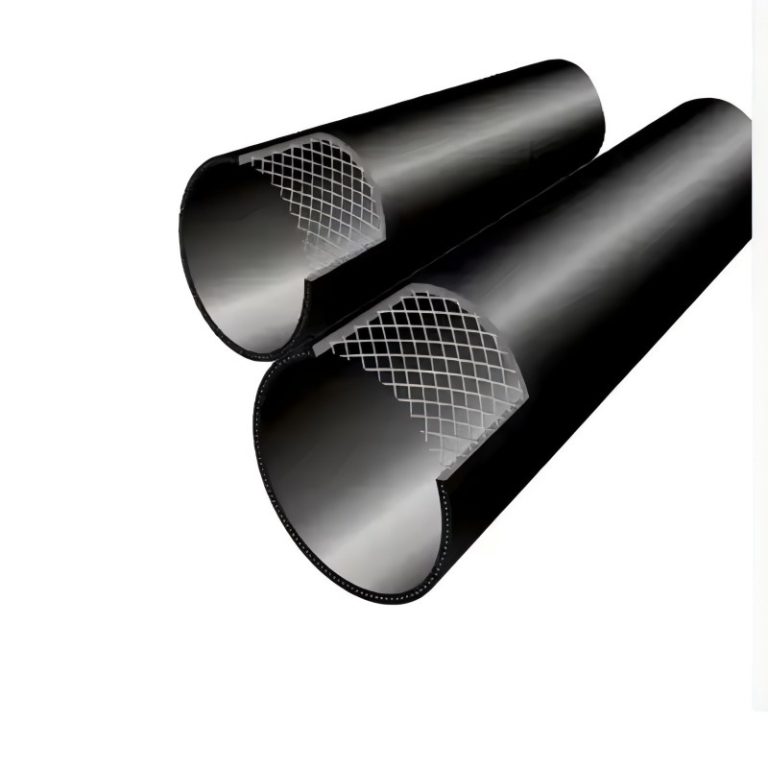

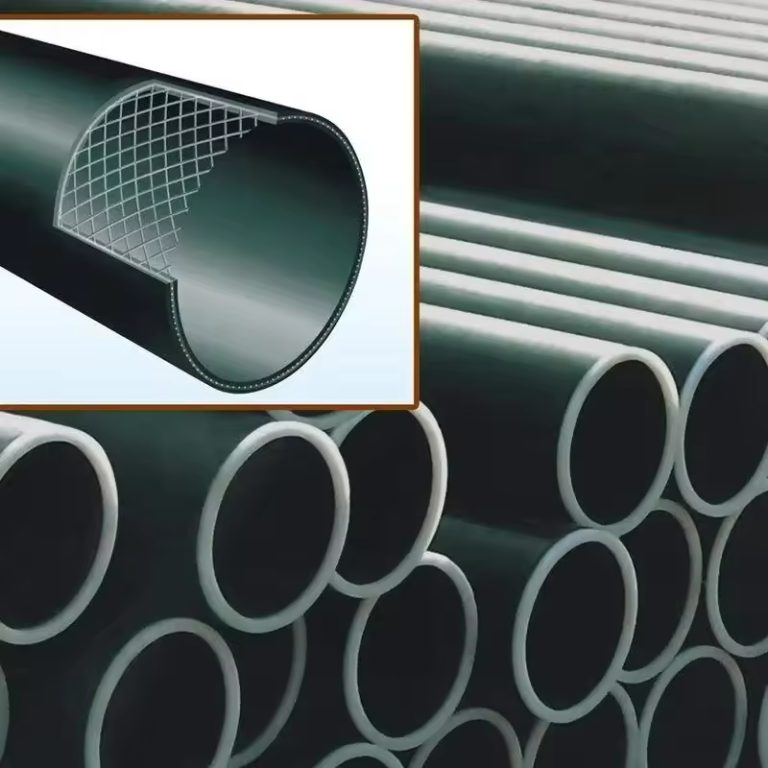

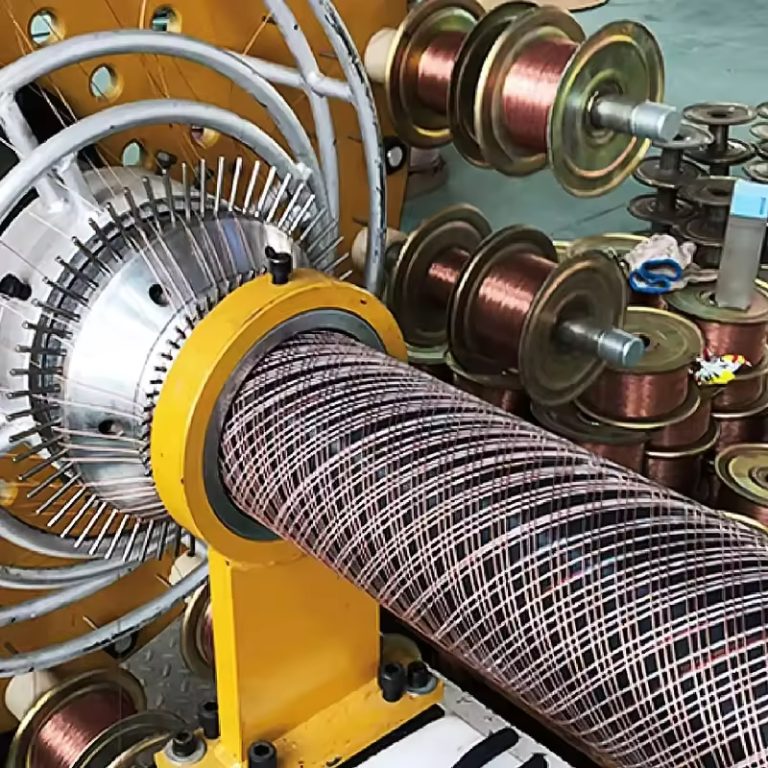

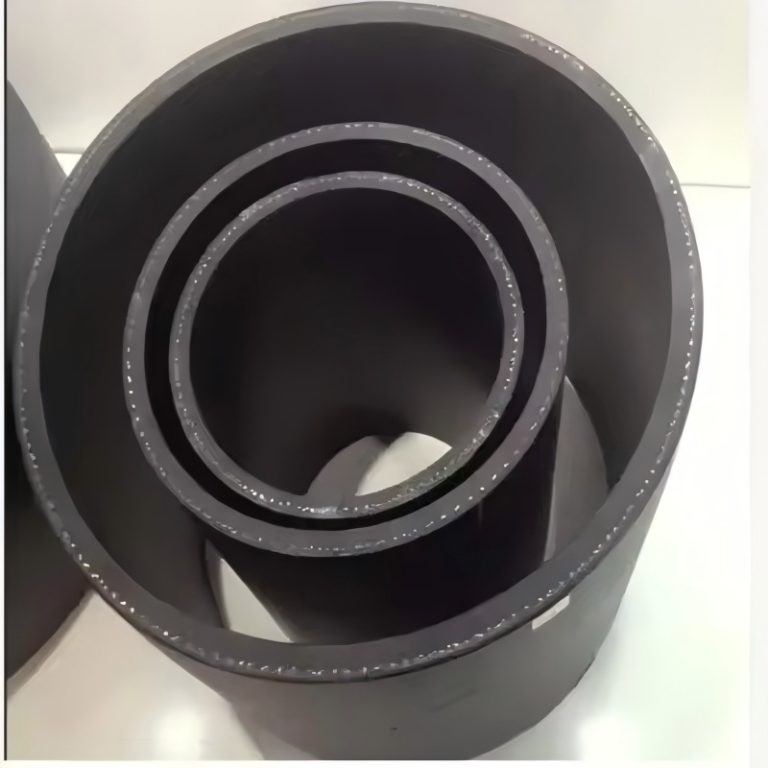

The HDPE Steel Wire Mesh Skeleton Composite Pipe (also known as SRTP or Steel Reinforced Thermoplastic Pipe) represents a significant advancement in piping technology. This high-performance composite pipe features a unique three-layer structure: an inner layer of virgin HDPE, a central reinforcement of high-tensile steel wire mesh, and an outer layer of HDPE. This design ingeniously combines the corrosion resistance of plastic with the mechanical strength of steel, creating a pipe suitable for medium and high-pressure applications in water and gas supply networks. It is engineered to deliver a service life exceeding 50 years, offering a durable and reliable solution for modern infrastructure projects.

Key Advantages

-

Exceptional Strength and Pressure Resistance: The spirally wound steel wire mesh skeleton provides superior resistance to internal pressure (rated from PN10 to PN25+), external loads, and soil stresses. This high ring stiffness prevents deformation and makes the pipe ideal for deep burial and demanding environments without the need for expensive concrete anchoring

-

Superior Corrosion and Chemical Resistance: Both the inner and outer layers are made from high-grade HDPE, making the pipe immune to rust, electrolytic corrosion, and a wide range of chemicals and abrasive media. This ensures long-term integrity and purity of the conveyed water or gas

-

Leak-Proof Joint System: The pipe utilizes electrofusion connection methods. This creates a monolithic, leak-free joint that is stronger than the pipe itself, ensuring a completely sealed system and preventing resource loss or environmental contamination

-

Lightweight and Easy Installation: Despite its strength, the pipe is remarkably lightweight (approximately 1/8 the weight of steel pipes), significantly reducing transportation and installation costs. Its flexibility allows for easier handling and bending around obstacles, speeding up project timelines

-

Hydraulic Efficiency and Long Service Life: The smooth HDPE inner surface (Manning coefficient: 0.009) ensures minimal flow resistance, increasing delivery capacity by up to 30% compared to conventional pipes and reducing pumping energy costs. The pipe is designed for a safe service life of over 50 years under normal conditions

.