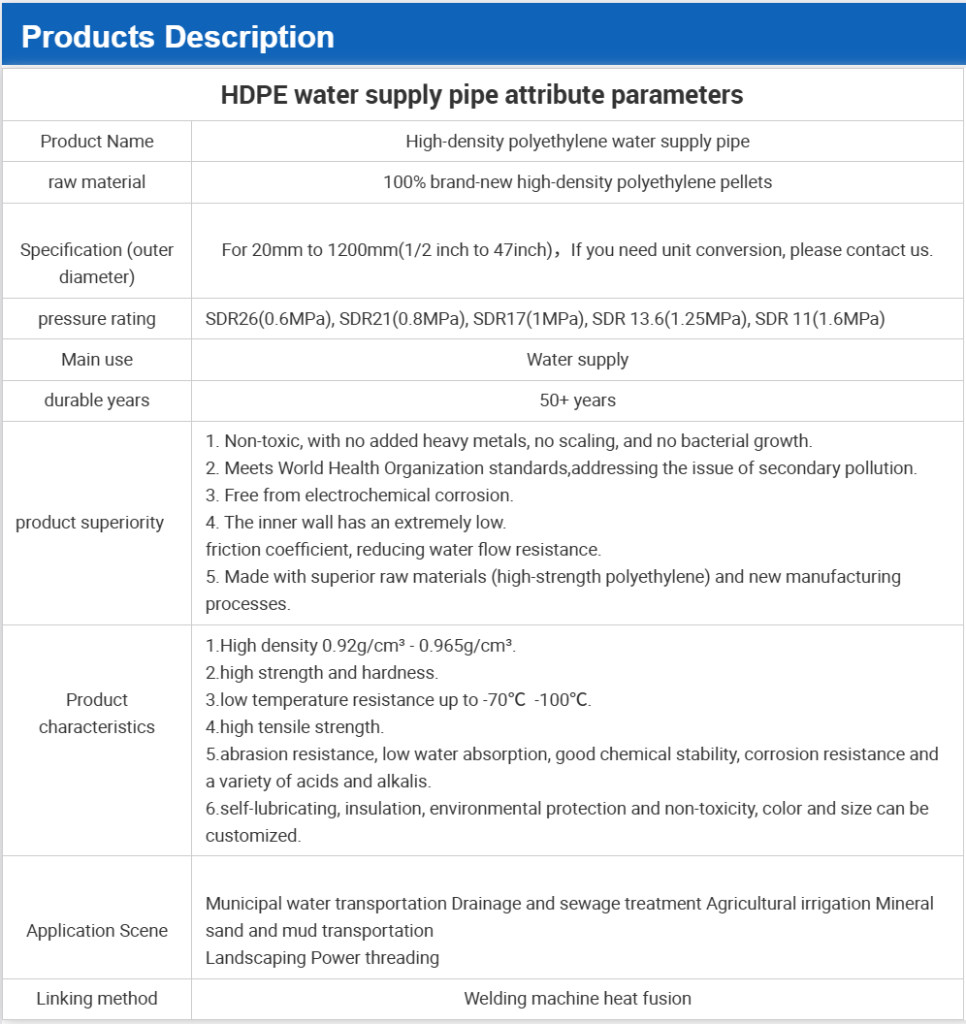

PE100 HDPE Pipe for Water Supply: Corrosion Resistant with 50-Year Lifespan

Product Overview

PE100 HDPE (High-Density Polyethylene) pipes are engineered for demanding water supply applications, combining exceptional durability, chemical resistance, and a proven service life of over 50 years

. Manufactured from premium PE100 raw materials, these pipes meet international standards such as ISO 4427, GB/T 13663, and ASTM D3035, ensuring reliability for municipal, industrial, and agricultural water systems.

Key Advantages

-

Superior Corrosion & Chemical Resistance

-

PE100 HDPE pipes resist corrosion from chemicals, acids, and alkalis, making them ideal for aggressive soil environments and industrial wastewater

. They eliminate rust, scaling, and electrochemical degradation, common issues with metal pipes.

-

-

Long-Term Durability

-

With a 50-year minimum service life, these pipes withstand temperatures from -60°C to 60°C and exhibit high impact resistance, even in seismic zones

. Their resistance to slow crack growth (SCG) and rapid crack propagation (RCP) ensures reliability under pressure fluctuations.

-

-

Leak-Proof Joints

-

Heat-fused (butt or electrofusion) joints create monolithic, leak-free systems stronger than the pipe itself, preventing water loss and contamination.

-

-

Hydraulic Efficiency

-

The smooth inner surface (Manning coefficient: 0.009) reduces friction, lowering pumping costs by ~30% compared to metal pipes

. This also prevents biofilm buildup, ensuring water purity.

-

-

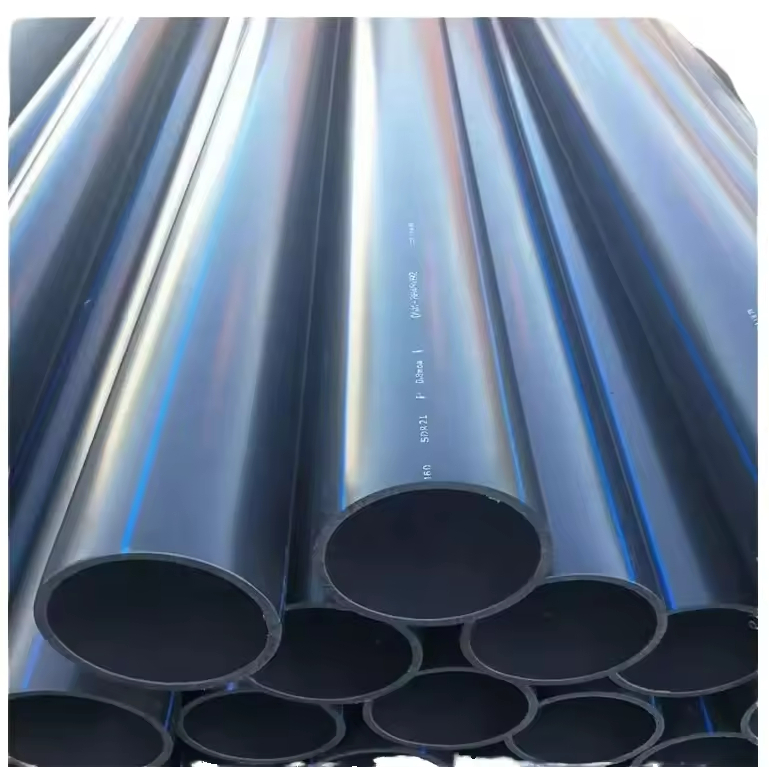

Lightweight & Easy Installation

-

Weighing 1/8 of steel pipes, HDPE pipes reduce transport and labor costs. Flexibility allows bending without additional fittings, enabling trenchless installation methods

-